Examine This Report on Material Test Lab

Wiki Article

The Material Test Lab Ideas

Table of ContentsGetting The Material Test Lab To WorkThe Ultimate Guide To Material Test LabA Biased View of Material Test LabExcitement About Material Test Lab

As a matter of fact, a lot of the most often-used metals and several plastics, polymers, fabrics as well as composites exhibit Hookean actions, which indicates the anxiety in a material is proportional to the pressure that created it. For suppliers, it is of the utmost relevance to comprehend the mechanical buildings of products that show some Hookean behavior during loading (material test lab).

The Ultimate Guide To Material Test Lab

Additionally, many territories have actually adopted regulation limiting using dangerous materials. In cases like these, governments as well as governing bodies established conformity requirements that have to be met by makers. Firms have to stick to these standards, which normally define examination procedures, to verify conformity. The quality of a material entering into a produced product is as essential as the dependability of the manufacturing procedure.With the wide array of materials as well as treatments offered in the market, testing can help tighten down the choices to one of the most suitable selection for the planned use. As stated in the past, for many market applications, testing is performed to license material to a provided criterion or requirements, or to validate that it meets other rigorous requirements prior to it is taken into use.

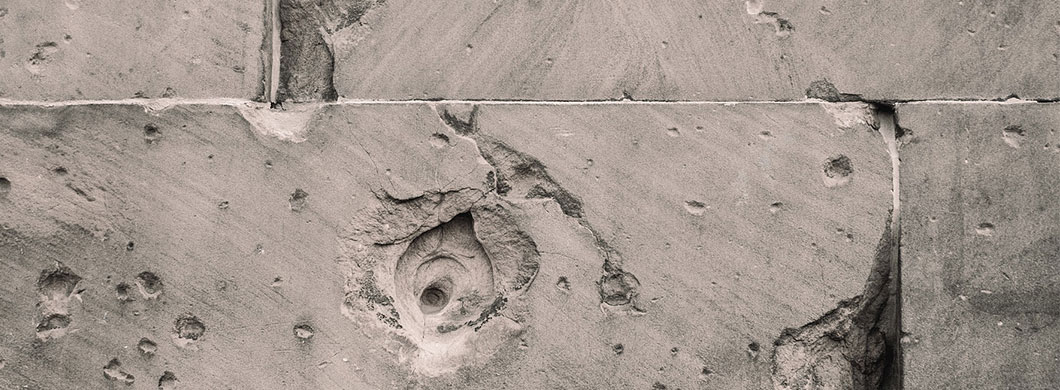

Rust testing can identify if the product will hold up under offered problems such as humidity or a seawater atmosphere. When an application needs extra long lasting or much more corrosion-resistant metals, this can commonly be obtained with the enhancement of therapies. When ideal, the product might be heat treated before testing to establish that the specified outcomes have actually been accomplished.

Material Test Lab for Beginners

Products Screening, additionally referred to as Building and construction Products Screening (CMT), is a crucial safety and security treatment performed before setting up materials right into a framework. CMT is a kind of quality assurance screening that occurs both on-site and in a laboratory. This process intends to examine products for compaction, stamina and security, as well as therefore figure out the viability of materials in a particular task. material test lab.

Olsen's device was revolutionary because it could perform tensile, transverse and compression tests within one maker. Additionally, the device was straightforward to run, economical as well as supplied higher accuracy. The application of materials testing includes a wide spectrum of products, as nearly any kind of resources might have its make-up evaluated for density, strength and also security.

The rope is made up of rubber, steel and foam. Examining products is an essential high quality control procedure for guaranteeing that the foam-covered manage will certainly not scrub visite site and discolor hands or that the rubber cord will not damage after a specific quantity of jumps. Products screening is a method existing in all durable goods as well as is a company for safety as well as trust fund.

4 Easy Facts About Material Test Lab Explained

Product screening and also site examinations are needed throughout the building procedure to guarantee a top quality job upon conclusion. While not all examinations are necessary for every single project, there are some crucial tests that can confirm to be crucial to most. The required services are identified by the sort of job, the land and location being constructed upon, and the solutions sites available for testing.Construction materialscreening can be separated into two groups: area testing, which takes place at the project website, and also laboratory screening, which entails taking examples from the task site back to an off-site area for further analysis. These dirt examples can be assessed in the field or repossessed to the laboratory for additional testing. The service technicians inspect for wetness as well as compaction, which will influence the structure's foundation. It appears apparent, but it is crucial to have a solid foundation, without problems, before building starts. This consists of the ground to be built upon and also the products utilized to build the structure. Without this testing, home builders and also designers will not understandthe top quality of the sub-surface and also products as well as whether they will certainly meet the project's demands. Various other kinds of area testing include: Soil and Aggregate Tasting as well as Testing, Compaction as well as Density, Bearing Ratio, Permeability Testing, Concrete Sampling and also Screening, Air Entrainment Screening, Depression Testing, Temperatures Unit Weight, On-site examinations are necessary to make sure compliance with the demands of the task documents and developing code. Site evaluation guarantees that any failures are detected as well as repaired appropriately before task completion. There are several tests that can be performed before, throughout, or after building to help in the consistency of the task. Flooring wetness analysis and also flooring flatness screening specify the safety and longevity of a concrete piece foundation. Laboratory testing on product examples such as soil, asphalt, aggregate, concrete, as well as masonry taken from the area site is a reputable technique to supply comprehensive additional reading analysis on the materials, making certain that the materials on a work website will not cause any project-related problems. Lab tests can likewise be performed if the area testing results show undetermined or a much more comprehensive evaluation is needed. Both sorts of screening as well as routine evaluations to check the building and construction development makes certain that quality assurance is maintained

throughout the job. Building and construction material screening is a regulatory need for the majority of large-scale building projects. Certain building material codes and also regulations might vary from state to state, but there prevail oversight organizations, consisting of ASTM International, U.S. Issue addressed; risk drawn away. If product screening and evaluations are not done during building and construction, any problems or failures that happen long after building and construction is completedcan cause litigation. Possible troubles consist of non-compliance with building ordinance, mold, rust that could result in material wear and tear, and also moisture, compaction, or air web content in the material that triggers serious architectural failures, also developing collapse. Such precautions will conserve the time and cost of renovating any type of work, prevent lawsuits, and also worst-case scenario, building breakdown or collapse. Boost Safety Consider material testing and also examinations as expansions of safety equipment. Like headgears, goggles, vests, and more, they are made for defense. While the outcomes might not seem immediate, ensuring that the products are structurally risk-free through testing and also assessments throughout the building and construction procedure boosts the structure's overall security and honesty. Her history consists of fenestration product screening, as well as geotechnical solutions for concrete, asphalt and also dirts. V. Ryan 2013- PRODUCTS TESTING- A FUNCTIONAL APPROACH An understanding of the residential properties and also usages of products, will certainly aid a developer throughout nearly every phase of the design process and also particularly during the advancement area. Initial study can be carried out by a basic examination of materials. When designing an item, an understanding of the residential properties of products will help figure out if a product is suitable for the manufacture of a productItem including any product you are designingDeveloping

Report this wiki page